The role of Precision aluminum casting in achieving excellence

The Future of Aluminum Foundries: Fads and Technologies Shaping the Market

The light weight aluminum factory market is going through considerable change. Secret trends highlight the relevance of sustainability and effectiveness. Advancements in wise manufacturing and automation are becoming common. Shops are increasingly concentrated on using recycled products. This change questions about future practices and modern technologies. Just how will these adjustments impact production methods and market characteristics? The solutions may redefine the market landscape in unexpected methods.

Innovations in Smart Manufacturing Technologies

As the light weight aluminum shop industry evolves, advancements in smart manufacturing innovations are coming to be significantly essential for boosting performance and efficiency. The combination of automation, man-made knowledge, and the Net of Things (IoT) is changing traditional foundry procedures. These modern technologies allow real-time monitoring of processes, permitting immediate adjustments that enhance output and minimize waste.

Machine learning algorithms evaluate production information to recognize patterns and anticipate maintenance demands, decreasing downtime. Robotics are progressively employed for repetitive tasks, freeing competent workers to concentrate on more intricate difficulties. Furthermore, electronic twins-- digital designs of physical procedures-- help with simulations that can improve design and operational approaches.

The fostering of these smart manufacturing technologies is driving affordable advantages in the light weight aluminum foundry market. By streamlining operations and improving decision-making capabilities, foundries can satisfy growing market demands while maintaining high-grade standards. The future of light weight aluminum foundries is unquestionably linked to these technical technologies.

Accepting Eco-Friendly Materials and Processes

The aluminum shop market is increasingly concentrating on environment-friendly products and procedures to enhance sustainability. This shift consists of the adoption of sustainable product sourcing, energy-efficient production methods, and efficient recycling and waste management approaches. By incorporating these methods, foundries aim to reduce their environmental influence while keeping competition in the market.

Sustainable Material Sourcing

Exactly how can aluminum foundries enhance their sustainability initiatives? Lasting product sourcing has emerged as an essential approach in accomplishing this objective. By focusing on recycled aluminum, factories can greatly minimize their ecological footprint, as recycled materials require much less power and fewer resources compared to main aluminum production. On top of that, sourcing materials from accredited providers that follow environment-friendly practices advertises responsible mining and minimizes environmental impact. Foundries are additionally discovering alternate materials, such as biopolymers and environment-friendly coatings, to match conventional light weight aluminum processes. Collaborating with stakeholders, including vendors and ecological organizations, promotes development in sourcing techniques. Ultimately, welcoming lasting product sourcing not only aligns with international sustainability objectives however likewise placements aluminum shops as leaders in environmentally liable manufacturing.

Energy-Efficient Production Methods

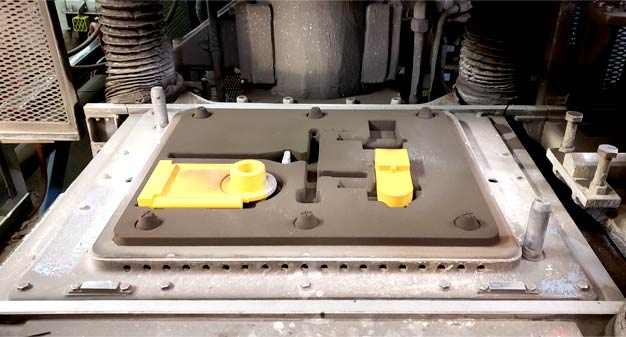

Light weight aluminum shops are increasingly adopting energy-efficient production techniques to enhance their lasting product sourcing efforts. These approaches concentrate on minimizing power usage throughout the production process. Advanced technologies, such as induction melting and enhanced casting procedures, are being carried out to decrease the general carbon impact. Additionally, automation and wise production systems boost operational effectiveness, permitting far better power management. Foundries are additionally checking out the assimilation of renewable resource sources, such as solar and wind, to power their procedures. By focusing on energy effectiveness, aluminum shops not just reduced manufacturing costs however likewise straighten themselves with global sustainability goals, making sure a more eco liable technique to light weight aluminum production while satisfying the rising demand for green techniques in the industry.

Reusing and Waste Monitoring

Accepting environmentally friendly products and processes, light weight aluminum factories are focusing on recycling and waste administration strategies to improve sustainability in their operations. By integrating closed-loop systems, these facilities are lessening waste and optimizing source performance. Scrap light weight aluminum, an easily offered product, is being reused on-site, greatly reducing the requirement for virgin materials and reducing power usage. Innovations in arranging and processing innovations even more promote the recycling of aluminum, ensuring that also contaminated products can be repurposed effectively. In addition, factories are embracing lasting methods such as lowering hazardous waste and promoting using eco-friendly products for product packaging. This dedication to recycling not only lowers environmental influence however also enhances the economic viability of light weight aluminum factories in an open market.

The Duty of Automation and Robotics

Automation and robotics are increasingly transforming the light weight aluminum foundry industry, substantially boosting production efficiency. By integrating sophisticated innovations, shops can decrease labor expenses while at the same time improving security standards for their workforce. This change not just enhances procedures yet also positions the market for sustainable growth in an open market.

Improved Manufacturing Efficiency

Revolutionizing production procedures, the assimilation of advanced robotics and automation innovations has come to be a keystone for aluminum factories looking for enhanced efficiency. These advancements streamline process, reduce cycle times, and enhance product top quality by reducing human error. Automated systems can keep track of assembly line in real-time, enabling immediate modifications that optimize output. Additionally, robotics facilitate the handling of dangerous materials, guaranteeing safer functioning settings while boosting throughput. Anticipating maintenance innovations additionally add to efficiency by preparing for equipment failings, thus reducing downtime. Because of this, aluminum factories can attain greater uniformity in their items while find more responding much more promptly to market demands. This welcome of automation is setting a brand-new requirement for performance and operational quality within the industry.

Lowering Labor Costs

The shift towards advanced robotics and automation in aluminum factories not just boosts manufacturing efficiency but also plays a substantial duty in lowering labor costs. By incorporating automated systems, factories can decrease the reliance on hands-on labor, which frequently involves high wages and training expenses. Robotics improve repetitive jobs such as putting, molding, and completing, permitting a higher output with fewer personnel. This technological change not only minimizes labor-related prices however additionally improves consistency and quality in production. In addition, automation can run all the time, optimizing functional hours without the connected costs of overtime or change differentials. As an outcome, aluminum foundries can attain substantial cost savings while maintaining affordable prices in a developing market landscape.

Improving Safety Criteria

While typical light weight aluminum foundry procedures usually subject workers to unsafe atmospheres, the combination of robotics and automation significantly boosts safety criteria within the industry. Automated systems can perform risky jobs, such as liquified steel handling and heavy training, minimizing human exposure to hazardous conditions. In addition, robotics can operate in hazardous ambiences and extreme temperature levels, properly decreasing the danger of injury. Advanced checking technologies and artificial intelligence assurance real-time safety and security assessments, enabling instant feedbacks to potential dangers. Moreover, automation enhances operations, reducing the probability of crashes triggered by human mistake. Therefore, the fostering of these modern technologies not only improves security however additionally fosters a much more effective and productive working atmosphere in aluminum shops.

Enhancing Power Efficiency in Manufacturing

As aluminum factories look for to preserve competitiveness in an advancing market, enhancing power performance in manufacturing has become an essential emphasis. By adopting innovative technologies such as high-efficiency melting furnaces and automated temperature controls, foundries can significantly lower energy consumption. Applying real-time surveillance systems permits specific tracking of energy use throughout the manufacturing procedure, making it possible for fast modifications to enhance effectiveness.

Furthermore, moving to alternative energy resources, including renewable options, can better lower the carbon footprint. The combination of energy healing systems, which redeem waste warm for reuse, is becoming increasingly usual. Training employees in energy monitoring methods guarantees that every person entailed in the production procedure bears in mind power use.

These campaigns not only reduced operational costs yet also straighten with worldwide sustainability goals, positioning light weight aluminum factories as responsible gamers in the industry while enhancing their total competitiveness. - Aluminum Foundry

Technologies in Recycling Light Weight Aluminum

Developments in recycling aluminum have actually acquired energy together with efforts to enhance energy performance in production. The aluminum market has actually embraced sophisticated technologies that improve the reusing procedure, decreasing energy usage and ecological impact. Methods such as hydrometallurgy and brand-new sorting modern technologies boost the removal of light weight aluminum from scrap, enhancing yield rates and making certain better recycled product.

Moreover, the development of closed-loop recycling systems enables factories page to recycle aluminum without significant deterioration in high quality, making the process much more sustainable. Advancements in logistics and collection, including improved radar and automated sorting, have likewise played an essential role in raising the performance of light weight aluminum recuperation. These innovations not just add to a round economic situation but also assist reduce the carbon footprint related to light weight aluminum manufacturing. As the need for sustainable practices expands, these innovations place the aluminum foundry sector as a leader in responsible source monitoring.

Reacting To Market Needs and Consumer Trends

Versatility has become a cornerstone for light weight aluminum foundries replying to developing market demands and customer fads. As sectors significantly prioritize sustainability, aluminum foundries are changing towards environment-friendly methods, including improved recycling processes and lowered carbon footprints. This shift straightens with consumer preferences for ecologically responsible items, driving shops to introduce their offerings.

In addition, the surge of light-weight products in automobile and aerospace sectors demands innovations in light weight aluminum alloys and casting techniques. Shops are investing in research study and growth to produce high-strength, lightweight parts that fulfill rigid efficiency requirements.

Modification has gotten grip, with consumers seeking customized remedies. Aluminum factories are leveraging advanced production modern technologies, such as 3D printing, to accommodate particular customer demands effectively. This responsiveness not just satisfies customer needs but also settings light weight aluminum shops competitively in a vibrant market landscape, ensuring their relevance in an ever-changing industrial atmosphere.

Regularly Asked Concerns

Exactly How Do Aluminum Foundries Impact Citizen Economies?

Light weight aluminum foundries substantially affect neighborhood economies by creating tasks, boosting demand for regional suppliers, and adding to community advancement. Their operations usually cause enhanced tax obligation earnings, which can money necessary public services and framework enhancements.

What Are the Security Rules for Light Weight Aluminum Factory Workers?

Safety guidelines for aluminum shop employees include compulsory individual protective tools, correct air flow systems, routine training on dangerous products, and adherence to guidelines set by occupational health read here and wellness and safety managements to lessen risks and warranty worker safety and security. - Aluminum Foundry

Exactly How Does Light Weight Aluminum Recycling Affect Global Supply Chains?

Aluminum reusing significantly reduces need for raw materials, boosts resource performance, and stabilizes rates. This shift influences global supply chains by cultivating a circular economic climate, advertising sustainability, and making certain a more resistant industry in varying markets.

What Career Opportunities Exist in the Light Weight Aluminum Foundry Sector?

Different career possibilities exist in the aluminum shop industry, consisting of roles in design, quality assurance, manufacturing management, and research study and development. Knowledgeable labor settings such as mold and mildew makers and maker operators are likewise popular.

How Do International Profession Policies Influence Light Weight Aluminum Foundries?

International trade policies considerably influence aluminum foundries by impacting import tolls, supply chain characteristics, and market accessibility. These factors can influence functional prices, competition, and overall success within the worldwide light weight aluminum production landscape.

By focusing on recycled aluminum, factories can greatly reduce their environmental impact, as recycled products need much less energy and fewer resources compared to main light weight aluminum manufacturing. Light weight aluminum factories are progressively embracing energy-efficient production techniques to complement their lasting product sourcing initiatives. Automation and robotics are progressively transforming the aluminum foundry market, substantially improving manufacturing effectiveness. The shift towards progressed robotics and automation in light weight aluminum shops not just boosts production efficiency however also plays a significant role in minimizing labor expenses. As aluminum foundries seek to preserve competitiveness in an advancing market, improving power effectiveness in production has arised as a critical focus.